Products

-

Semi-Automatic Toilet Paper And Roll Paper Packing Machine

Main technical parameters:

1.Packing speed: 8-12 bags/minute

2.Power supply voltage: 220V, 50HZ

3.Air supply voltage: 0.6MPA (client should prepare this by himself)

4.Total power: 1.2 KW

5.Packing size (L×W×H): Length(250-500)x Width(100-240)x Height(100-150)mm

6.Packing Rolls No.: 4, 6, 8, 10, 12 rolls/bag

7.Machine size: 3800mm x 1200mm x 1250mm

8.Machine Weight: 600KGS -

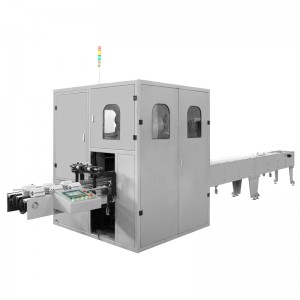

HX-08 Bagging And Sealing Machine (Includes Automatic Transmit Device)

It can push paper into bag and then seal the bag automatically. The transmit device can transmit paper forward for packing automatically.

-

Toilet Roll Paper Bagging & Sealing Machine

Main performance and features:

1.Mainly used for semi-automatic packaging machine of Toilet roll paper bag packing machine, this machine can automatically split the toilet roll paper into two rows, accurately count, can pack single layer and double layer.After manual bagging, automatic bagging sealing and blowing waste.2. PLC computer programming control, touch screen display parameters, parameters can be set to the relevant system, can set the number of packaging on the touch screen to achieve man-machine dialogue, more accurate control.

3. The machine can be operated by one person, which can reduce the manufacturing cost and management cost of the enterprise and reduce the production space.

4.The machine has reasonable structure, stable performance and strong material.

5. Induction before work, so that workers use more secure.

6. The same machine can pack products of various specifications.

-

HX-2100H Non-Stop Toilet Paper Rewinding Production Line

Equipment introduce:

1.Non stop, continuous rewinding

2. Each part is controlled by servo motor, and the mechanism is simple, greatly reduce the failure rate.

3. Servo motor control the speed , cut paper on the perforating line, stable and accurate;

4. The PLC touch screen control system is adopted to realize precision control, which ensures accurate and clear perforation, and the paper roll tightness is suitable.

5. Man-machine interface regulates the pitch of the perforation.

6. The embossing unit and the gluing lamination unit can be used to produce various kinds of toilet paper and kitchen roll paper with different patterns. -

HX-220A Full-automatic Napkin Paper Packing Machine

1. Packing Speed: 25-35 bags/minute

2. Packing scope:

L:120-210mm

W: 80-110 mm

H: 40-100 mm

If the customer’s product packaging size is not within this range, please kindly provide a specific product packaging size

3. Packing film material: CPP or OPP Double sides heat sealing film. Film thickness: 0.04-0.05 mm

4. Main Machine overall size (L×W×H): 2544 x 2600 x 2020mm;(be subjected to practical machine)

5. Machine power: About 6 KW (380V 50HZ)

6. Whole machine weight: About 2.1 tons. (be subjected to practical machine). -

HX-2400B Gluing Lamination Toilet Paper Kitchen Towel Production Line

Equipment Introduction:

The Kitchen Towel and Toilet Paper Roll Production Line (A professional production line for producing kitchen towel paper and Toilet Paper Roll).Customers who need to order this production line, please contact us!This production line can produce the products as followings:

1.Kitchen towel paper with glue lamination and two color printing

2.Kitchen towel paper with glue lamination

3.Toilet paper Roll with glue lamination

4.Edge embossed Toilet paper roll. -

HX-Z200 Automatic Log Saw Cutting Machine (Double Passway)

Equipment Function and Configuration:

1. This machine is special equipment for cutting small rolled toilet paper and kitchen paper. Production operation is simple, product cut is trim, and production speed is high.

2. Adopts programmable controller to automatically control production. Automatic reset, push roll, cut. The roll-cutting length, cutting period can be adjustable.

3. Automatically check rolled paper head, automatically ablate the untidy and eliminate waste.

4. Equipped with touch screen man-machine dialogue to control the operation, production parameter and trouble is clear to see, operation is simple.

5. Photoelectric inspecting, servo driving, pneumatic component and bearing cutter, etc adopt good quality product.

6. Having automatic blade grinding device. Accuracy of blade-grinding is high, side door safety protection switch, equipment automatically stop when door is opened. -

HX-2000B Toilet Paper And Lazy Rag Rewinding Production Line

Equipment Introduction

1. Adopt PLC programmable control, independent motor drive, the whole machine wall panel.

2. Man-machine conversation, easy operation with high efficiency. Perforating distance and tension control digital operation.

3. Machine stop when raw paper broken, jumbo Roll Paper is pneumatically uploaded onto machine.

4.The rewinding process of the product is tight first and loose afterward, with its tension adjustable. Automatic changing paper roll, rewinding, tail cutting and sealing, then finished log auto unloading.

5. Bearing, electric component and synchronous belt use famous brand. -

HX-SC4 Single Channel Log Saw Cutting Machine

1. The machine is for small Jumbo roll paper cutting , simple and easy operation, product incision smooth.

2. Adopt PLC programmable automatic control, automatic reset push roll, cutting. The length and diameter of cutting roll are adjustable.

3.Automatic detection of paper roll cutting head. The min head and tail cutting is 25mm

4. Touch screen man-machine dialogue control, all production parameters, production failure at a glance, easy to operate.

5. Supporting automatic blade grinding device, high precision blade grinding, side door safety protection switch, when the door is opened, the equipment will automatically stop.

-

Automatic Log Saw Cutting Machine For Hand Towel Facial Paper

Equipment Function and Configuration:

1. This machine is special equipment for cutting hand towel paper kitchen towel, facial paper. Production operation is simple, product cut is trim, and production speed is high.

2. Adopts programmable controller to automatically control production. Automatic reset, push paper, cut. The paper-cutting length, cutting period can be adjustable.

3. Automatically check paper head, automatically ablate the untidy and eliminate waste.

4. Equipped with touch screen man-machine dialogue to control the operation, production parameter and trouble is clear to see, operation is simple.

5. Photoelectric inspecting, servo driving, pneumatic component and bearing cutter, etc adopt good quality product.

6. Having automatic blade grinding device. Accuracy of blade-grinding is high, side door safety protection switch, equipment automatically stop when door is opened. -

HX-2200B Glue Lamination And Lazy Rag Rewinding Machine

Equipment Introduction

1. Adopt PLC programmable controller, separate motor drive, tension control adjustment is adjusted on the operating screen.

2. Man-machine conversation, easy operation with high production efficiency. Machine stop when raw paper broke.

3. Equipment production process:

Two jumbo roll stands (Pneumatic lifting raw paper)—One group of Embossing and glue lamination unit —one set of steel to steel embossed( for produce lazy rag with embossing heating)—-pressing and conveying device—-perforating unit —-rewinding unit —Tail trimming and gluing(including auto discharge) -

Facial Tissue Log Saw Cutting Machine

1. This machine is a special for cutting equipment for tissue paper. The production operation is simple and easy, the cutting is smooth, and the production speed is high.

2. Use programmable device to automatically control the production process. Automatic reset push and cut. Roll length and cutting cycle can be controlled.

3. Equipped with touch screen man-machine dialogue control, all production parameters and production faults are clear at a glance, easy to operate.

4. Optoelectronic testing, servo drive, pneumatic components, bearing tools and other high-quality products.

5. Equipped with automatic knife sharpener. Blade grinding precision is high, side door safety protection switch, when the door is opened automatically stop the equipment.