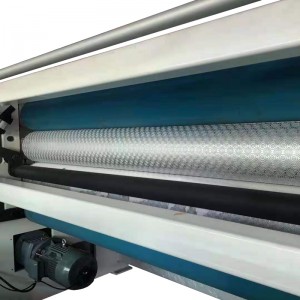

HX-2900Z Gluing Lamination System for Non-stop paper Roll Rewinding Machine

Main technical parameter

1. Design speed: 300 m / min

2. Production speed: 200-250 m / min (The maximum speed can reach to 500m/min, can be customized)

3. Jumbo roll paper width: max. 2900mm

4. Protection: the main transmission parts must be protected by protective covers

5. Equipment power: 22 kw (Based on the actual produced equipments)

6. Equipment weight: About 7 Tons (Based on the actual produced equipments)

7. Equipment size (length * width * height):

1960*2850*4000 mm (Based on the actual produced equipments)

Product Show

The gluing lamination system can also be configured on the machine of Toilet kitchen towel Rewinding machine, N-fold Hand towel paper machine, and V-fold hand towel paper machine, which greatly reduces the investment cost of the manufacturers.

Product Video

Product Description

Write your message here and send it to us