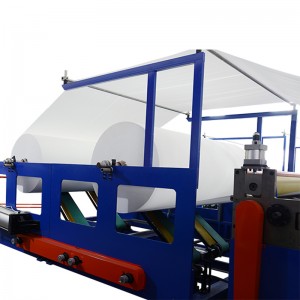

HX-2800B Automatic Kitchen Towel Paper Machine Production Line

Main technical parameter for 2800B rewinding machine:

1. production speed:about 100-180M/min

2.Rewinding diameter:100-130mm

3. Perforating distance: 100-240 MM

4. Jumbo roll width: ≦2800MM.

5. Jumbo roll diameter: ≦1200MM;

6. Equipment power:about 15.4KW(380V 50HZ)

7. Equipment weight:about 11.2T

8. Equipment overall size(L * W * H): 11000*3500*2300MM

Main technical parameter for paper roll storage rack

1. Introduction:It is for storing logs which producing from the rewinding machine

2. Log length:2800mm

3. Log diameter:100-130mm

4. Effective log Qty:80 logs

5. Equipment power:4.4KW,380V 50HZ,3phase

6. Equipment overall size (L×W×H):4300*4000*2500mm

7. Equipment weight:about 3 Tons

Main technical parameter for log saw cutting machine:

1. log length:2800mm

2. log diameter:φ100~φ130mm (can be customized)

3. production speed:cutting times 30-60 cut/min×2rolls/time

4. Equipment power: 5.57KW(380V 50HZ 3PHASE)

5. Equipment weight:about 3.5 Tons

6. Equipment overall size(L * W * H):8200*2020*2300mm

Product Show

Product Video

Product Description

Payment & Delivery

Payment Method: T/T,Western Union, PayPal

Delivery Details: within 75-90 days after confirming the order

FOB Port: Xiamen

Primary Advantage

Small Orders Accepted Country of Origin Experienced Machine

International suppliers

Product Performance Quality Approvals Service of Technicians

We have abundant Experience of producing most kinds of living paper machine device which were customized by customers from different countries and areas, so we can meet varies demand. If you have demand, welcome to contact us and create new values.